Sourcing and Supply Chain

To ensure high standards in product quality and efficiency, we mainly source our products through independent manufacturing partners located in Asia. In addition, to maximize responsiveness, we follow a local-for-local sourcing approach, wherever reasonable. We acknowledge adverse social and environmental impacts within our supply chain and drive actions to mitigate and reduce those impacts. With the consumer in mind, we aim to support our markets in having the right product available at the right point of sale at the right point in time.

Long-term relationships with independent manufacturing partners

To ensure high standards in product quality and efficiency, we outsource almost 100% of our production to independent manufacturing partners with the vast majority located in Asia. Strong capabilities around materials and processes have been built up in close collaboration with our strategic suppliers in this region over several decades. While we provide them with detailed product specifications that cover technical and sustainability dimensions, they possess excellent expertise in cost-efficient, high-volume production of footwear, apparel, and accessories and gear. By valuing long-term relationships, we can ensure that this expertise continues to grow: 68% of our independent manufacturing partners have worked with adidas for at least ten years, and 37% for over 20 years.

Length of relationship with independent manufacturing partners

Local-for-local sourcing for maximum responsiveness and flexibility

With our responsive and flexible sourcing model, we are able to react quickly to changing order patterns. In close collaboration with our wholesale partners, we are continuously assessing sell-through and can replenish product that is particularly sought-after during the season. This helps us to effectively reduce inventory risk and drive incremental net sales and higher margins by reducing initial order sizes.

We have continued to increase our local-for-local sourcing in several markets such as Greater China, India, Brazil, and Argentina. For example, we have set up an operating model in Greater China that enables end-to-end lead time reduction for articles requiring higher in-season responsiveness. We have improved market order efficiency and now produce the vast majority of product for the local market in Greater China. In addition to ensuring higher responsiveness, we constantly monitor the political and regulatory environment across the globe and avoid transferring goods between countries that would trigger increased trade tariffs.

Vietnam as our main sourcing country

In 2024, Vietnam remained the largest sourcing country, accounting for 27% of adidas total volume (2023: 26%), followed by Indonesia at 19% (2023: 19%) and China at 16% (2023: 16%). Overall, 92% of our total 2024 volume was produced in Asia (2023: 90%). Our largest factory produced approximately 5% of the total sourcing volume (2023: 4%).

Share of sourcing volumes by product category and country

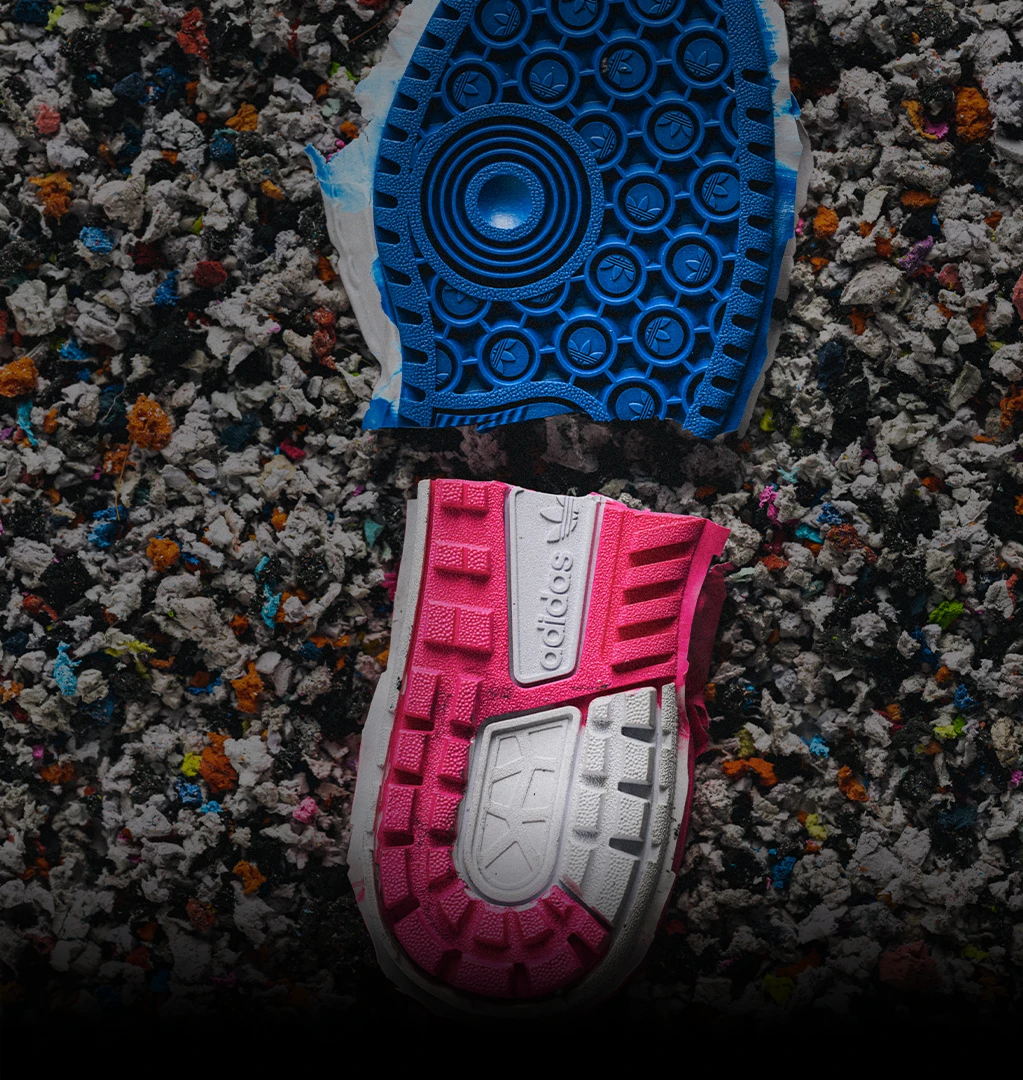

Reduction of adverse impacts throughout our supply chain

Greenhouse gas emissions from manufacturing are a major contributor to our CO2e emissions. To address this, we work with our suppliers to set decarbonization targets, including, but not limited to, increasing the use of renewable energy sources, the adaption of more sustainable materials, and demonstrating progress toward targets that are aligned with the Science Based Target initiative (SBTi). We incentivize suppliers for their decarbonization performance through product allocation priority and market share opportunities. We also expect our suppliers to reduce water consumption at Tier 2 factories and to use chemical formulations that achieve the highest conformance level with ZDHC Manufacturing Restricted Substances List (ZDHC MRSL) standards. By mapping and addressing deforestation risks, we manage the impact of our supply chain on biodiversity.

To ensure that we focus on both environmental topics and the interests of the workers in our supply chain, we have established the Human Rights and Environmental Due Diligence (HREDD) framework. This guides internal risk assessment and risk management processes in accordance with the United Nations (UN) Guiding Principles on Business and Human Rights and the Organisation for Economic Co-operation and Development (OECD) Guidelines for Multinational Enterprises and is in line with our Human Rights Policy commitments and other regulatory obligations, including the German Supply Chain Due Diligence Act. SEE SUSTAINABILITY STATEMENT

Serving consumers and partners through global distribution center network

After production, our products are shipped primarily by sea to our global distribution network of 60 distribution centers, 21 of which are company-owned and 39 of which are managed by logistics partners. These centers are strategically located across the globe. To enhance product availability, around half of the centers serve all channels, while the other half are tailored to specific channels or services. This set-up ensures that our products are available when and where the consumer wants them. SEE MARKETS AND SALES CHANNELS